Day 23 – Horizontal stabilizer – Back to metal work!

- Fred

- 0

- on Sep 03, 2022

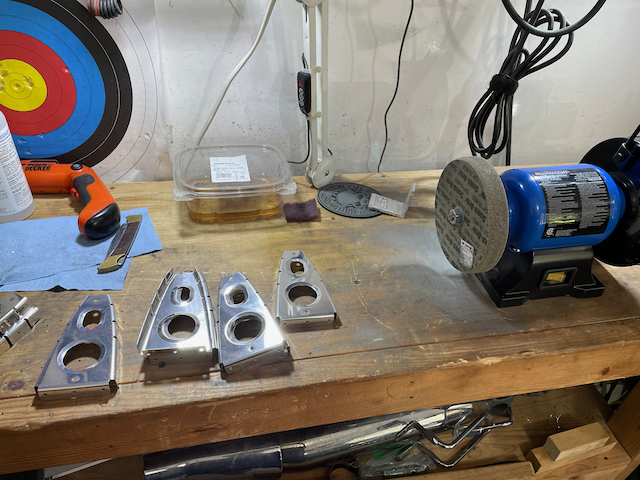

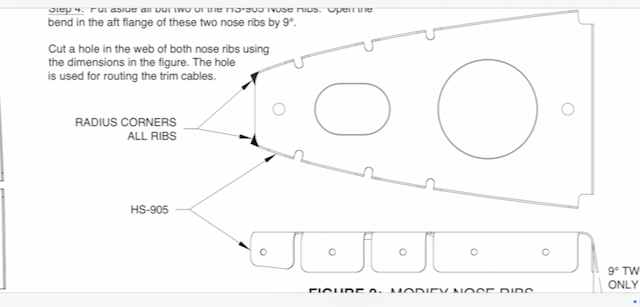

With my woodwork done (good enough), it’s time to get back to the metalwork! I found that a bunch of the ribs and noses still needed work. Lots of deburring and radiusing of parts. This was a new thing for me and caused a bit of confusion. The instructions say to radius to nose ribs and when I looked at the diagram, it looked like I may end up short for “edge distance” with the rivet that will be closest to the leading edge. I posted a few pictures and a question about this in a Facebook group, and I also sent off a message to vans builder support. The response I got from Facebook was somewhat varied. Some said I should grind away a fair bit of material, others said to just smooth the edges that are there, and one person suggested bending the edges back instead. Vans builder support also replied but were a bit less specific. Every response though shared one common thread: don’t sweat the edge distance too much for this part, because that last rivet is not a significant contributor to the structural integrity of the wing.

Today was also the first day in a bit that I’ve got to cleco a bunch of parts together. It’s always soo satisfying to see big pieces going together. You just have to pretended that you are not soon going to be tearing it all apart again! To help hold the spar in place while I hit it with clecos and ribs, I made up a little overhang on the workbench. This was handy cause I could flip the whole works upside down and back as needed. I put some scraps on the ends of the 2x2s to keep the work from falling off if I bump it. I am pretty sure the next step is taking this apart and doing a better job of radiusing the nose pieces, but for the moment, I can enjoy this fairly large part coming together!