Day 17 – Horizontal Spar Attachment Bracket

- Fred

- 0

- on Aug 24, 2022

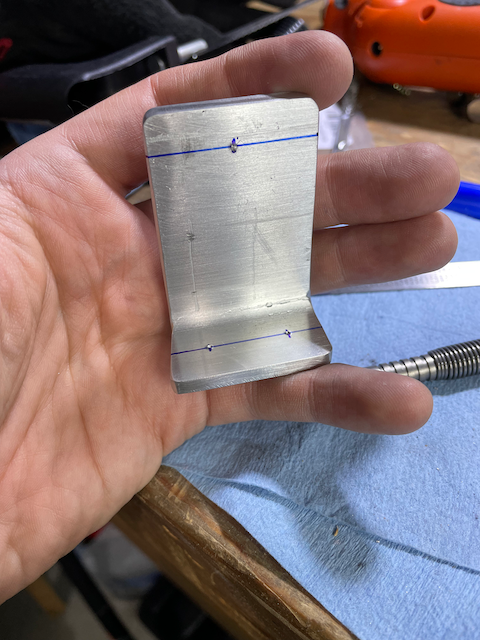

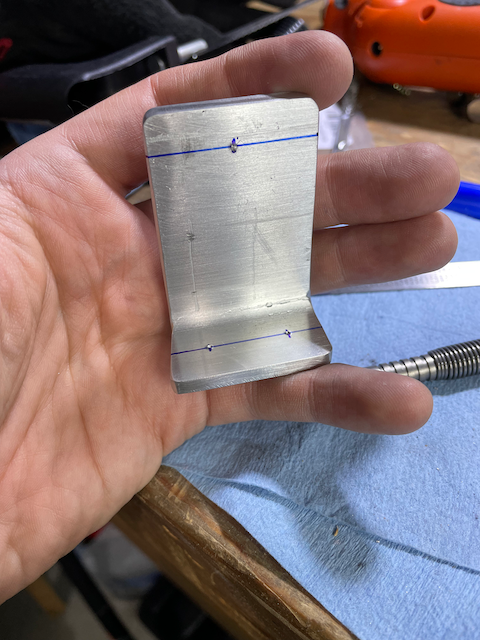

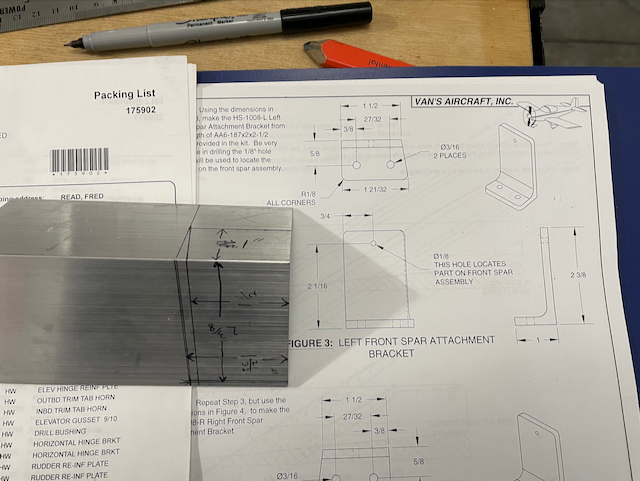

Last night I got to do a little manufacturing. The task was to build a horizontal spar attachment bracket. This is the first time I’ve had to work with material this thick.

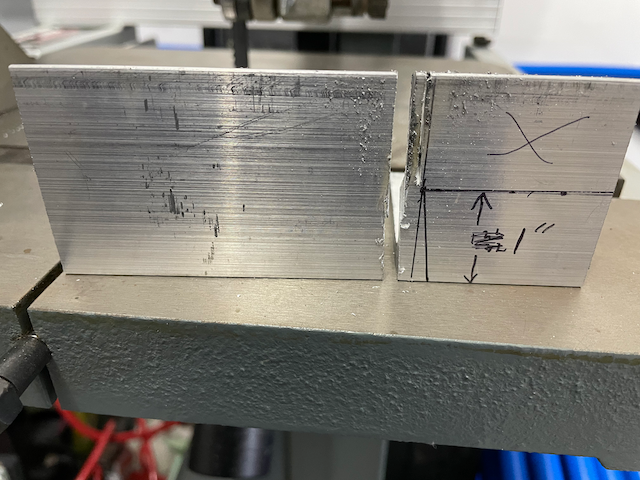

My first challenge was to measure out all the cut lines. Being “over 40”, I did a lot of this under a desktop magnifier to get the measurements perfect. I also pre-marked the little lines on my steel rulers so that I would not be continually counting 32nd marks. This strategy paid off several times throughout the night.

With all my lines drawn out, and re-measured a few times, I set out to make the cuts. My game plan was to cut “close to the line” and grind to perfection. This strategy worked several times before with thinner pieces like the skin stiffeners in the rudder. There were two big problems with my plan: 1) The bandsaw can’t cut strait and does not have the correct blade for my work. 2) the grinder wheel I have just clogs up and takes forever to get through the thicker material. The best solution ended up being to use a hacksaw for the initial cuts, and a vixen file for the shaping. I remember someone pointing that out in an earlier post, and this is where I finally took that advice.

With all my cuts done and the lines smoothed out with the file, a quick round with the Scotch-Brite wheel finished the piece nicely. The last step of the night was to mark and punch the holes that I’ll be drilling next time.